- Menu

- ProductsFeatured ProductsGeotextilesGeogridsReinforced Soil SystemsBlock Retaining SystemsGabionsTurf MattingGround CoversEarth AnchoringDewatering & DrainageDrainage CompositesImpermeable LinersPermeable PavingGeocellsRock BagsSheet Piles

- Contact Us

Microplastics in the environment

Facebook

LinkedIn

Twitter

WhatsApp

Let’s talk about microplastics in the environment, focusing on the potential impact from plastic products used in civil engineering, known as polymer-based products.

Microplastics come from various items we use every day, such as clothing, household items, stationery, packaging, and personal hygiene products like masks and gloves. While all these things can contribute to microplastics, we’re specifically interested in the impact of polymer-based civil engineering products.

Defining microplastics can be a bit unclear, but they are generally considered to be plastic particles smaller than 5mm but larger than one micron. Anything smaller than one micron is usually called nano-plastics.

There are two main sources of microplastics: primary and secondary. Primary microplastics are intentionally made in small sizes for specific purposes, which doesn’t apply to the civil engineering products we’re discussing. Secondary microplastics come from the breakdown of larger items. We’ll explore how this breakdown relates to microplastics in civil engineering products.

The types of civil engineering products we’re talking about are:

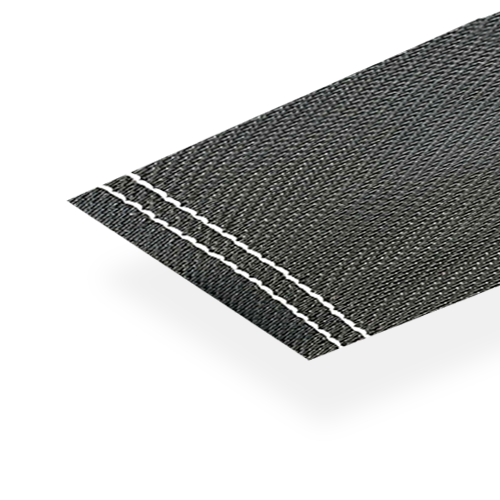

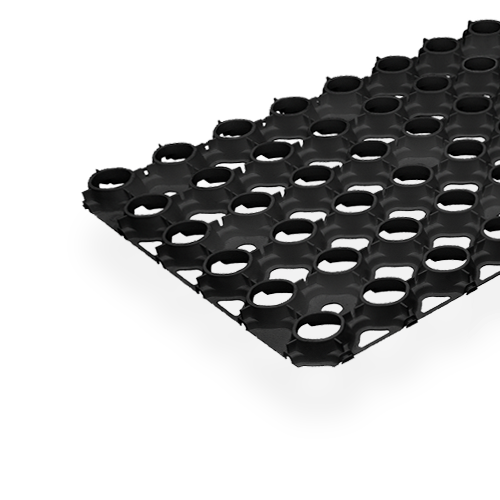

- Geogrids for reinforcement in soil, mechanically stabilised earth walls and embankments

- Geogrids for stabilisation in pavements

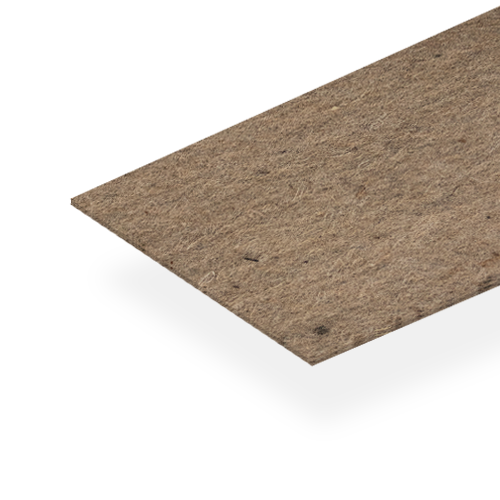

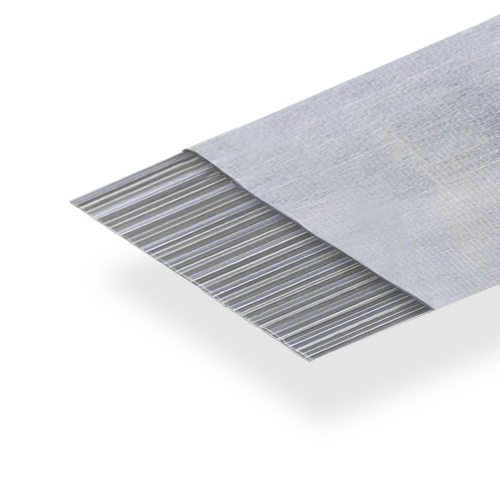

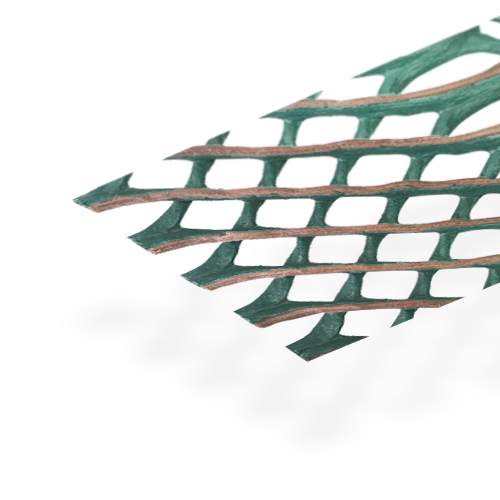

- A wide range of civil engineering fabrics

- Erosion and sediment control products

These items are specifically engineered for applications in civil engineering and infrastructure development. However, a critical inquiry arises: do these items introduce microplastics into the surrounding environment?

Our contention is that they do not. Let’s delve into more details.

Essentially, polymer-based products undergo degradation through two primary mechanisms.

- Physical abrasion: In natural settings, these products may experience friction, leading to the detachment of small plastic fragments.

- Chemical or UV degradation: This occurs when the product undergoes self-degradation, independent of external contact, resulting in the release of small particles.

These products, commonly referred to as geosynthetics, can be further categorised based on their intended usage—either above ground or below ground.

Above Ground Use:

It’s a slightly different story if we put these products above the ground. The two places we generally see these products above the ground are:

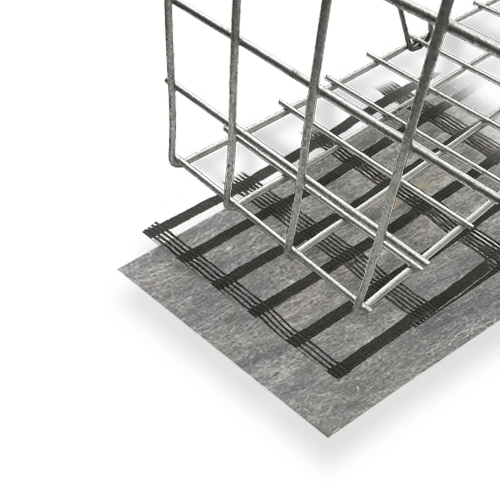

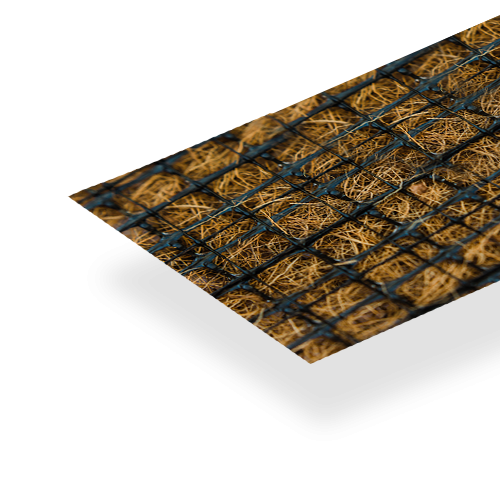

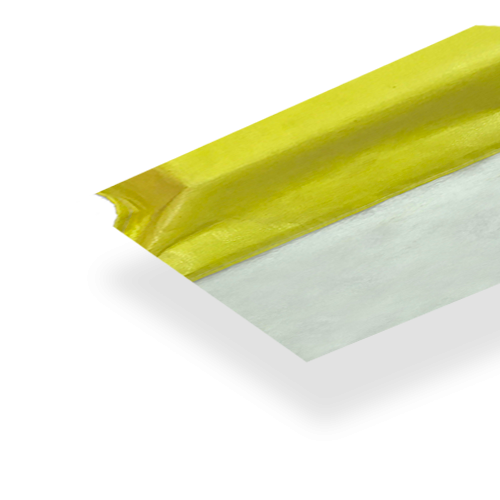

1. Geotextiles used for temporary erosion protection on construction sites.

- Once exposed, these products normally have an intended design life of between six months and two years.

- If we put a product that’s designed to be buried above the ground, we are at risk of abrasion and UV degradation.

- So, we design the product to be used above ground.

To do this, we do two different things to that product.

- Firstly, we will use a UV protected product.

- Secondly, we will calender the surface. Calendering is when we put a heat roller over the surface to bind those little fibres together, so that they do not break off and flow into the waterway.

Remember. If drainage products designed to be used underground are used on the surface, there is a risk of creating microplastics.

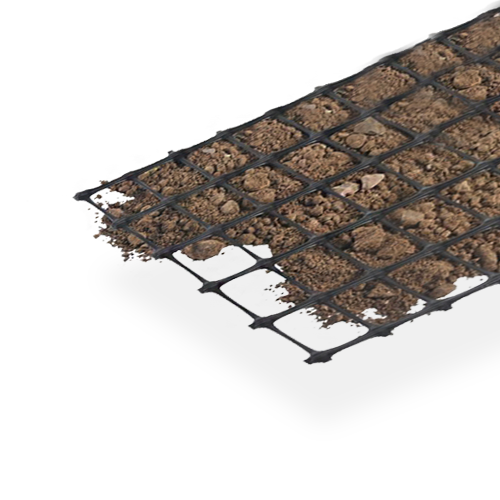

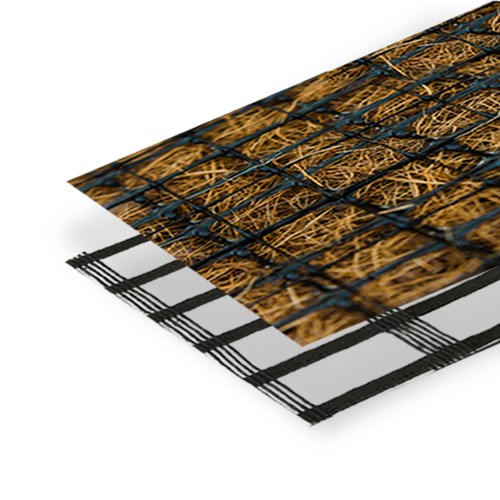

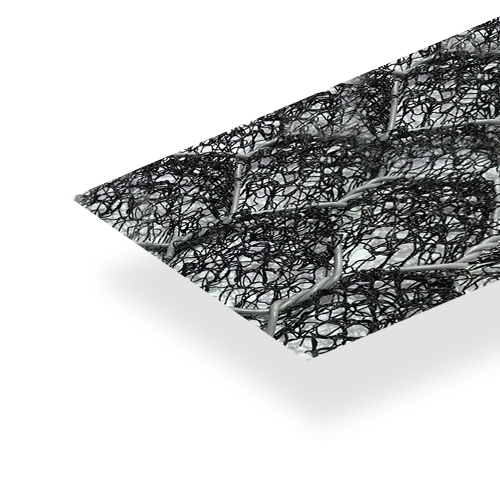

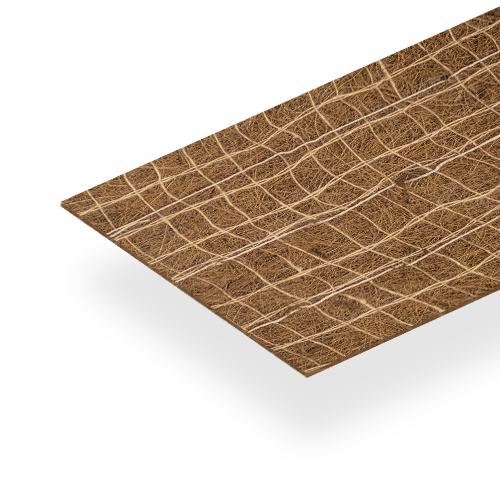

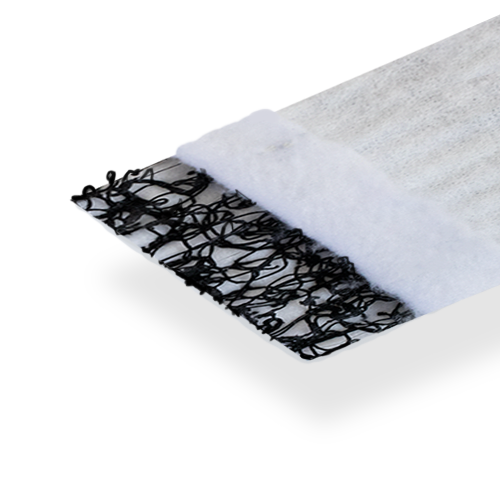

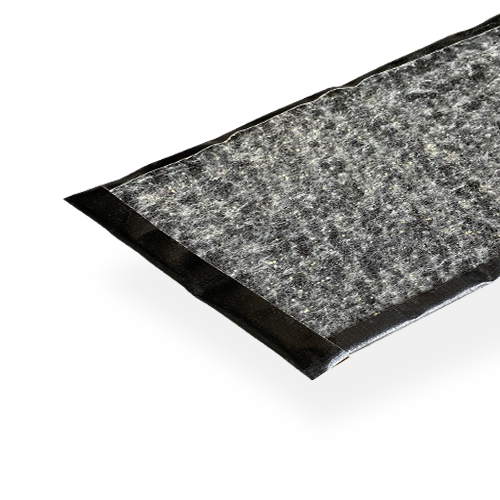

2. Erosion control matting.

- These use biodegradable materials, such as coconut fibre, instead of plastics.

- If coconut fibres break off into the environment, they will completely degrade.

- Some also use a black, UV stabilised polymer-based product as a backing that acts as a soil stabilisation grid.

If the loose fibres on a product like this were actually plastic, then that would be a danger of creating microplastics, so we only use UV stabilised polymer-based carrier layers and biodegradable products above ground for erosion control matting.

We also embed products such as ECC3 and BioCoir into the root zone, not the foliage zone. So, if you’ve got a swale drain protected with erosion control matting, for example, then that will be completely out of the sunlight anyway.

Below Ground Use:

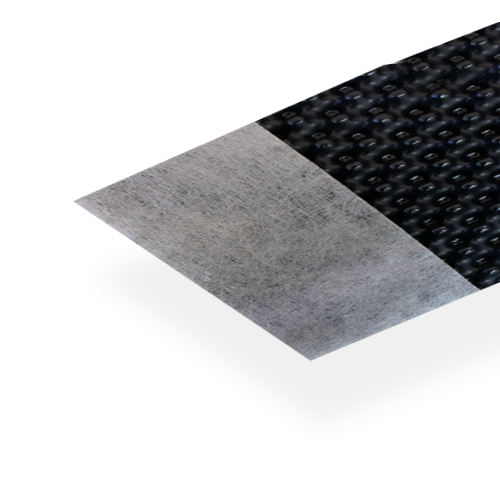

The majority of these products are used below the ground. Geogrids and the engineering fabrics are almost always used below ground. This means that, apart from a very small amount of abrasion when they are first installed, which they are designed to withstand, there will be no further abrasion over their design life.

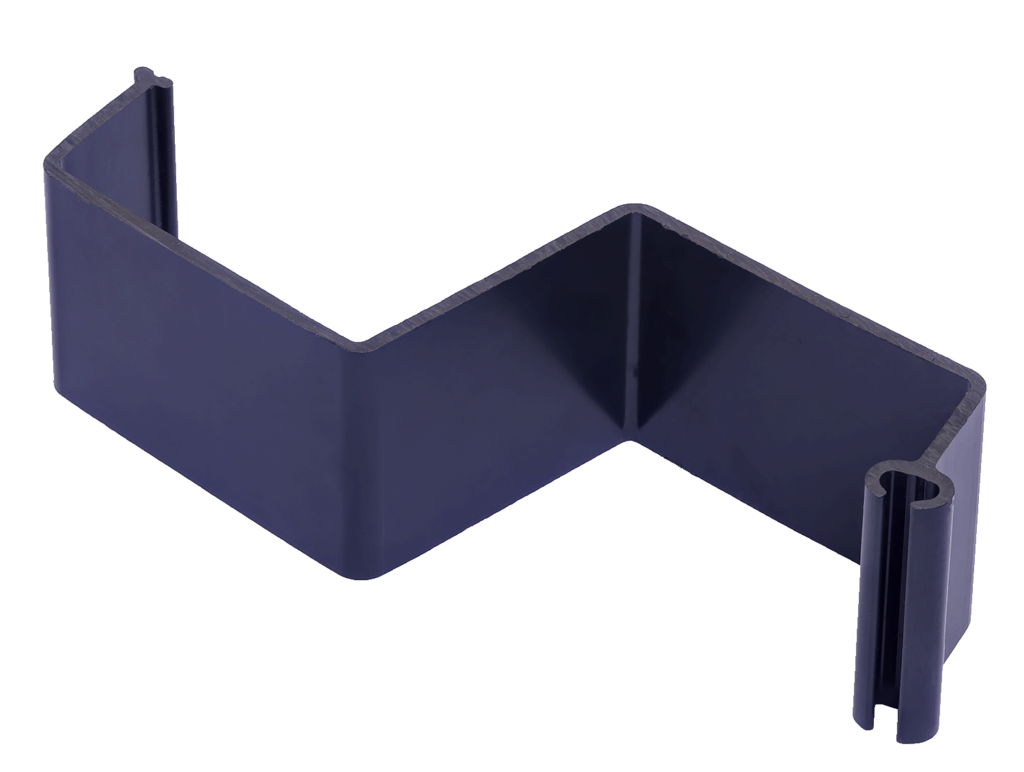

The design life of these products is very long, usually more than 100 years with no physical abrasion. At the end of that design life, they can be recycled. They are environmentally friendly products, especially when we consider what they’re replacing. Drainage composite, for example, is only about 200-300g of polymer per square meter. It can replace hundreds of kgs of quarried rock traditionally used for drainage, but focusing on our topic today, we can prevent geogrids and fabrics from generating microplastics by engineering them for a hundred-year design life and putting them in an application where there is no abrasion or exposure to UV light.

Other forms of chemical degradation, and hydrolysis and oxidation which are applicable to polyester and polypropylene fibres respectively, are also controlled when they are buried and out of the environment as regards sunshine and rain.

Any hydrolysis or oxidation that may occur is considered in design and addressed with either polymer additives or appropriate reduction factors to ensure the product does not degrade to the point of breakdown. Very few polymer products have this level of long term design consideration.

This means we’re not getting breakdown causing microplastics from either abrasion or chemical degradation when they’re placed underground.

In general, single use plastics are very different to engineered long-term plastics. We produce long-term plastics to last for over 100 years, and we engineer them into a project so they don’t generate microplastics in the environment. Engineered plastics also save vast quantities of other natural resources, such as quarried products, and we can demonstrate significant carbon-friendly benefits from the use of these engineered polymer-based products.