- Menu

- ProductsFeatured ProductsGeotextilesGeogridsReinforced Soil SystemsBlock Retaining SystemsGabionsTurf MattingGround CoversEarth AnchoringDewatering & DrainageDrainage CompositesImpermeable LinersPermeable PavingGeocellsRock Bags

- Contact Us

Scholey Street Shared Pathway – Platipus® Civil Anchors

Facebook

LinkedIn

Twitter

WhatsApp

Project Details

Contractor

Bridge and Civil

Client

The City of Newcastle

Engineer

Royal Haskoning DHV

Location

Islington, Newcastle

Project Information

The Scholey Street Shared Path is a $4 million project with construction having commenced in March 2016. This work forms part of the John Holland Rail Country Regional Network (JHRCRN) bridge construction which includes the construction of a new bridge and reinforced earth (RE) wall approaches at the Scholey street site. This shared path is the latest addition to the original scope of work.

Design

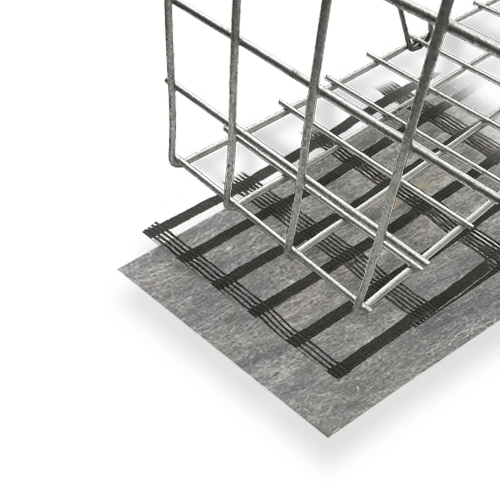

As part of a foundation system for an elevated shared pathway alongside an RE wall, permanent active ground anchor systems were deployed by Cirtex Australia.

The composite deck bridge structure is resting on a series of CFA piles interconnected by cast in-situ concrete head-stocks. Platipus anchoring systems were detailed and designed to provide lateral restraint to the bridge foundations in order to prevent any eventual overloading of the RE wall built and designed previously by others.

The design life expectancy requirement of the project was 100 years. Platipus S8 aluminium bronze anchor heads with 8mm diameter stainless steel tendons were supplied to meet the design requirements.

Installation

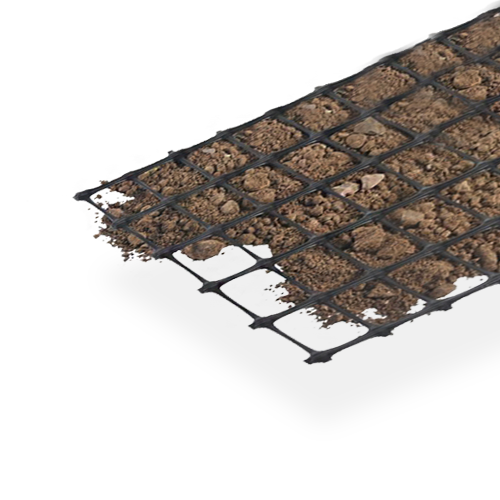

Anchors were driven at 30 to 45 degree angles and at a depth of 5m into the RE wall backfill. A pre-tension of 15kN working load was applied on site directly for the purpose built brackets through hydraulic jacks

The Platipus system provided the following key benefits:

• ‘Buildability’ & ease of installation – effective & efficient installation with all 7 anchor systems being installed and tested in 4 hours

• Loads were immediately verified after installation providing full confidence in all stakeholders

• No messy grouting, load uncertainty or delay in testing

• Total (supply & install) cost savings over traditional solutions

Products used in this Project

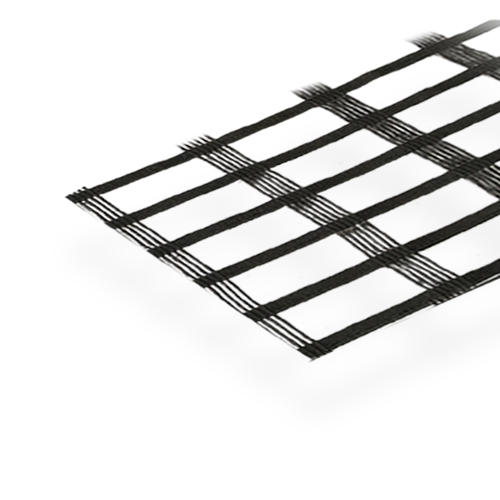

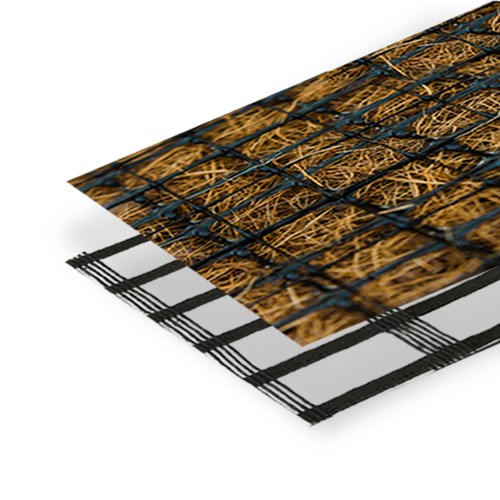

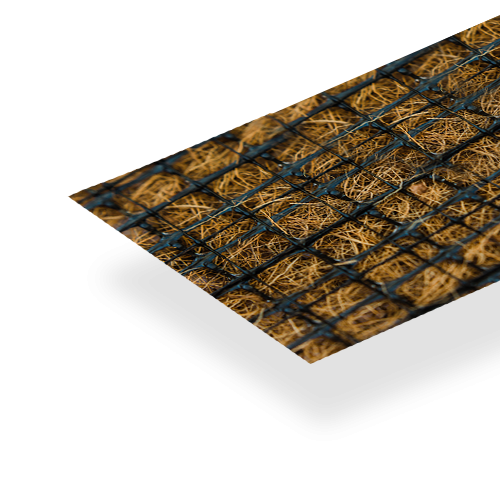

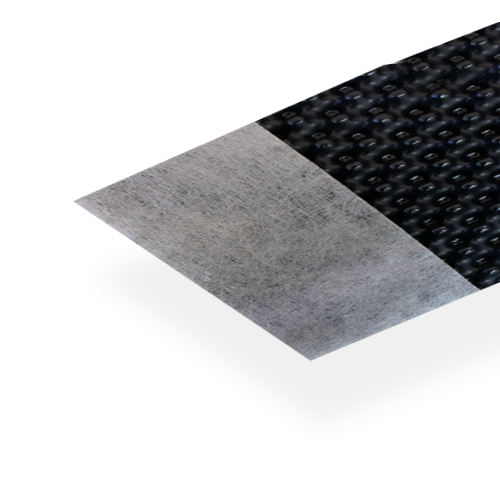

DuraForce AS series geotextile is manufactured and tested to exact quality standards...

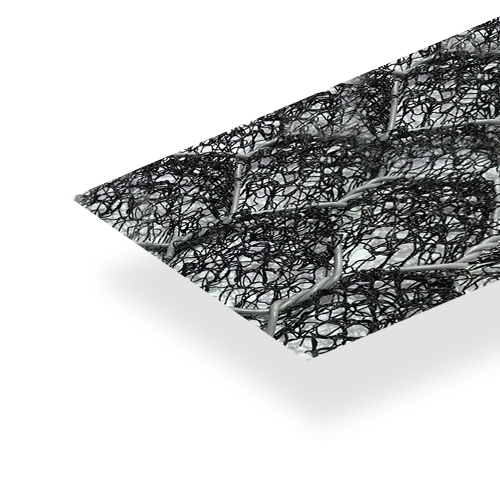

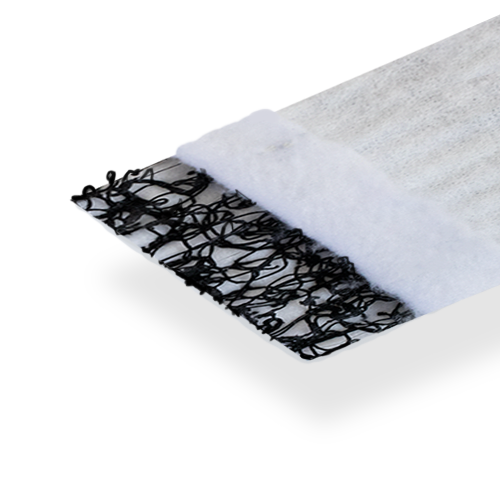

DuraForce® K geotextiles are an extremely robust nonwoven staple fibre geotextile, suitable...

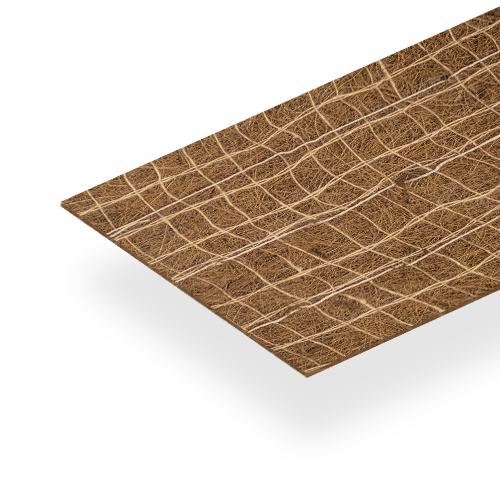

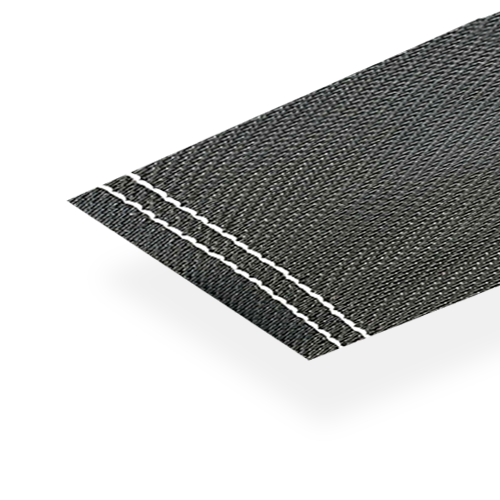

DuraForce® woven geotextile is suited to applications requiring both separation and reinforcement.