- Menu

- ProductsFeatured ProductsGeotextilesGeogridsReinforced Soil SystemsBlock Retaining SystemsGabionsTurf MattingGround CoversEarth AnchoringDewatering & DrainageDrainage CompositesImpermeable LinersPermeable PavingGeocellsRock Bags

- Contact Us

Sheet Pile Reinforcement – Platipus® Civil Anchors

Facebook

LinkedIn

Twitter

WhatsApp

Project Details

Contractor

Icon Co Pty (NZ) Ltd & CLL Service and Solutions Limited

Client

N/A

Engineer

Soil & Rock Consultants

Location

6-8 Munroe Lane, Auckland, New Zealand

Project Information

A new six level purpose-built 26,675m2 office block with a 212 space car park in the basement was being constructed on Munroe Lane Auckland. The building footprint covered the majority of the site. This resulted in the requirement for temporary retaining around the perimeter of the property to allow excavation and construction of the footings and basement to be completed.

Design

Due to the depth of the excavation, the sheet pile retaining had to have additional anchors to retain the surrounding soil. During construction there was plant, machinery and personal operating within the retained zone so it is critical every anchor achieved the required load. In the anchored zones there were variable soils types so the Platipus Earth Anchor system was chosen as the most suited anchor type for this project.

Installation

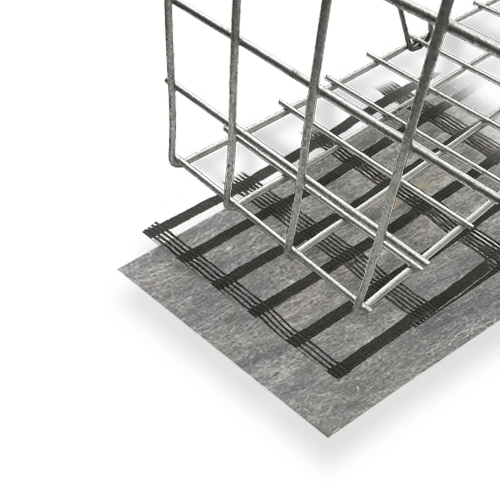

Sheet piles were installed from the existing ground level prior to excavation. During the staged excavation from within the sheet piled area the Platipus Earth Anchors were installed.

Platipus Earth Anchors are a percussion driven system and can then be immediately loaded upon completion on installation as there is no grout curing time as required with alternative anchor systems. As part of the standard installation process every anchor is load locked which provides the engineer with immediate performance data of each anchor. This allows the engineer design flexibility as the project progresses and assurance that critical design factors are being met.

The products used provided the following benefits to the project:

- No grout, no mess, no contamination, no curing time

- Every anchor tested to an exact holding capacity and made fully operational immediately

- Anchor Heads size can be adjusted on site to allow for variable soil conditions

Products used in this Project

The Platipus® Earth Anchor System is a percussion driven system that can...