- Menu

- ProductsFeatured ProductsGeotextilesGeogridsReinforced Soil SystemsBlock Retaining SystemsGabionsTurf MattingGround CoversEarth AnchoringDewatering & DrainageDrainage CompositesImpermeable LinersPermeable PavingGeocellsRock Bags

- Contact Us

Geotextile and Geogrid – Doing the basics better

Facebook

LinkedIn

Twitter

WhatsApp

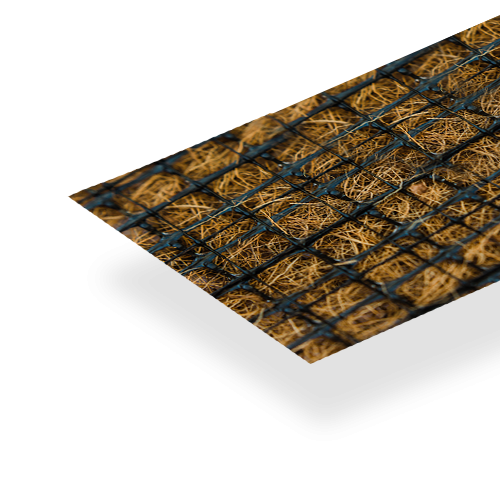

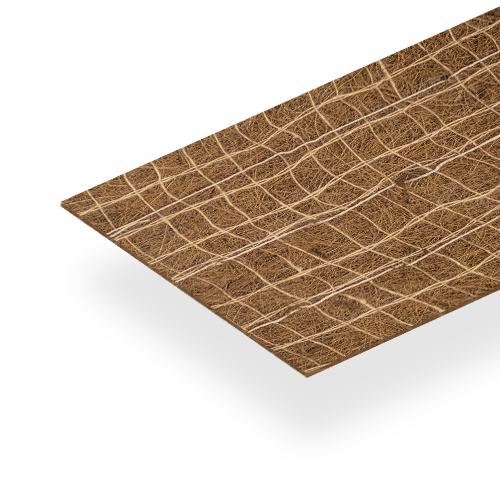

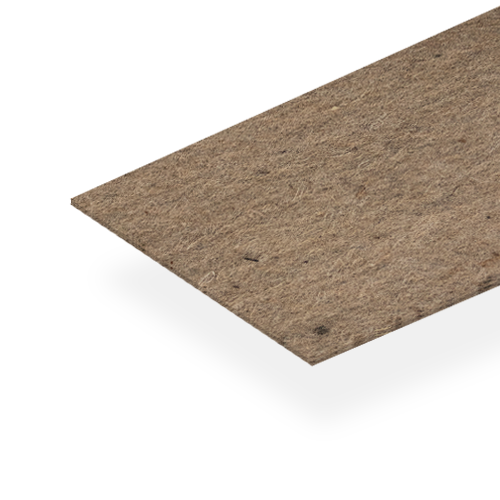

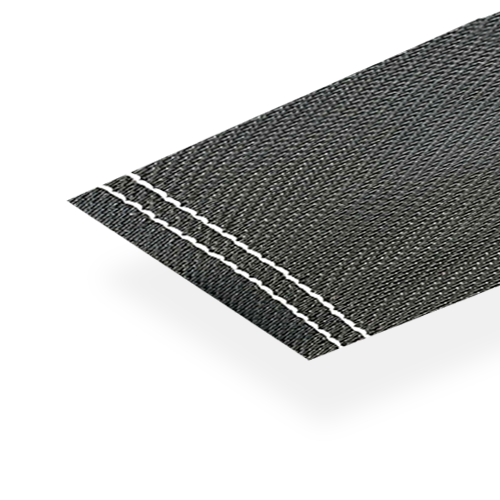

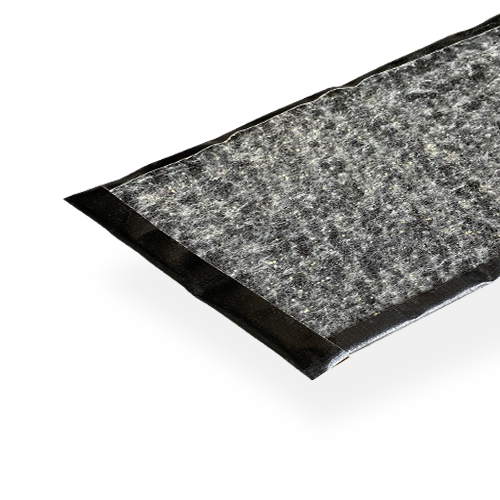

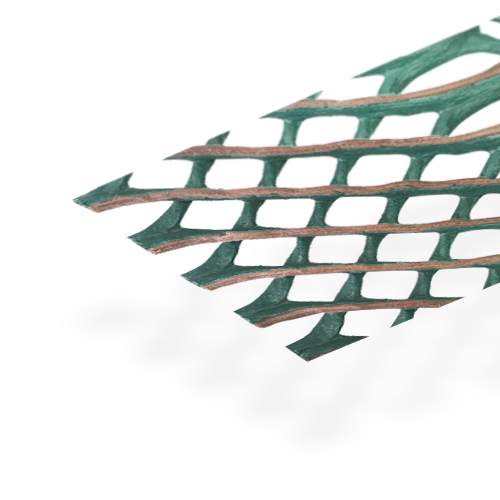

With geotextiles and geogrids becoming ever more popular and integrated in a wide variety of civil works, it is easy to become complacent as to the selection and use of the correct grade and type of product to perform the engineering function we are looking to achieve.

Whether we are working as a consultant, contractor or a client we have a professional responsibility to best practice and responsible use of resources. This includes the correct selection and use of products on whatever project we are working on.

This is a large responsibility especially as time and margins seem to be getting ever more constrained and the push for efficiency forever seems to rise as the most pressing need. However, in the field of geosynthetics for infrastructure, this responsibility also becomes one of our major opportunities, because if we can harness the maximum effect of these technologies, we can gain an unfair advantage over the rest of the market.

Choosing the best product by function

What function do you need, which project parameters will affect your choice and are you over-specifying or under-specifying?

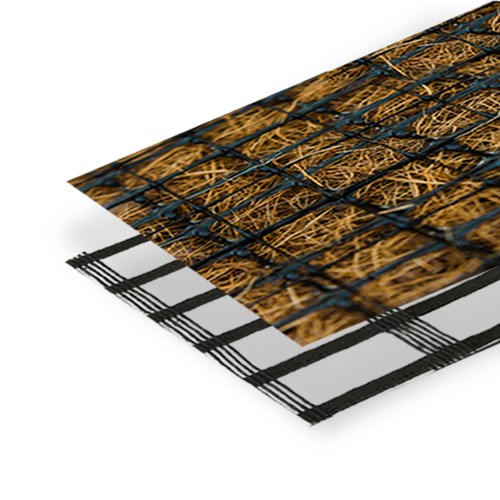

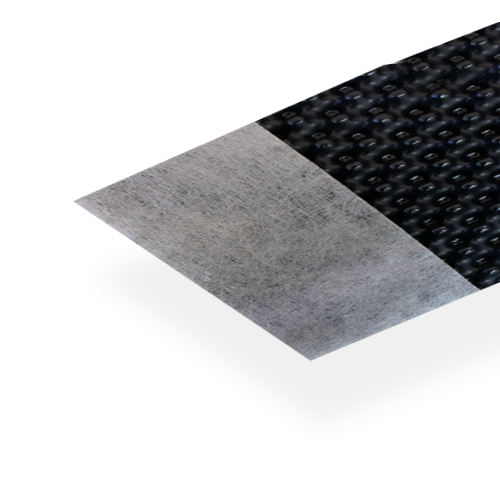

Any time you select or apply a geosynthetic product it is vital that you know exactly which engineering function you require it to perform. Once you are clear on this you will be a long way to selecting the correct product from an ever-increasing range available. In addition to knowing which function you require; it is helpful to consider any specific project parameters which will affect your choice. A few common site conditions that can affect a geosynthetic choice are conditions such as extreme heat sources, high chemical concentrates and prolonged UV exposure. An example may be a geotextile for asphalt reinforcement which will be in contact with extreme heat, or a drainage composite for a landfill application which may be exposed to harsh chemicals. For an overview of the engineering functions of geosynthetics please click though to our previous blog Geotextile, geogrid, or both?

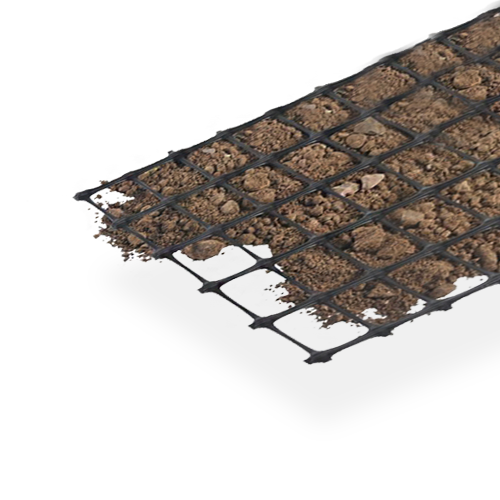

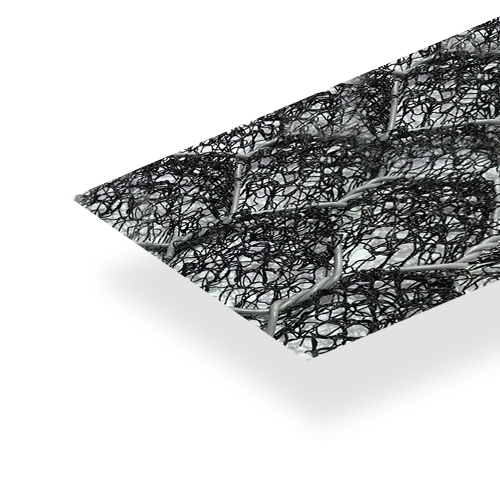

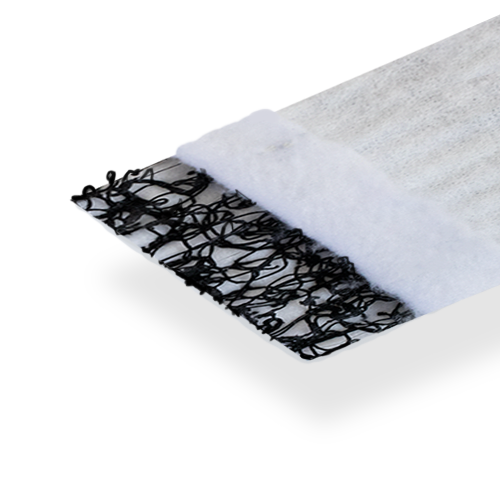

Reinforcement versus stabilisation

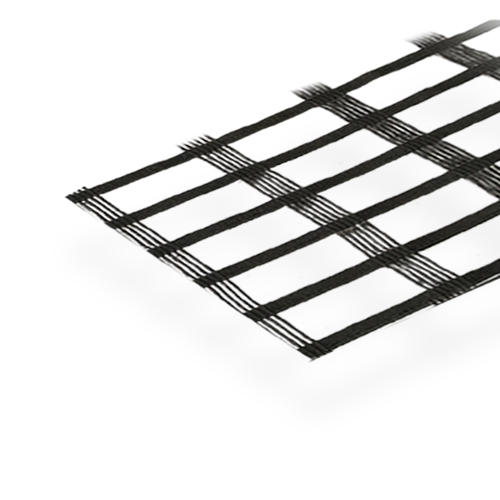

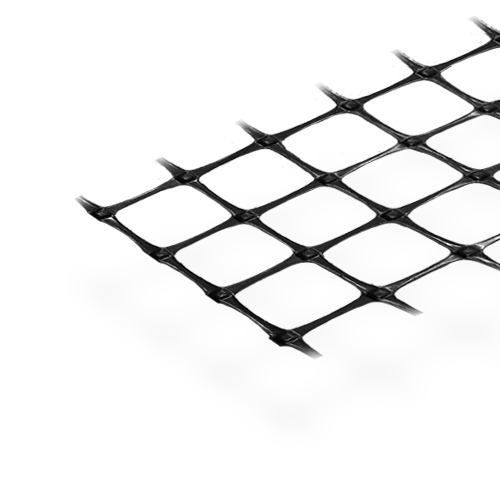

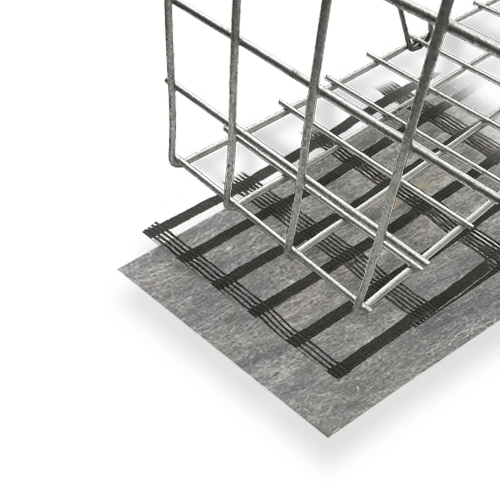

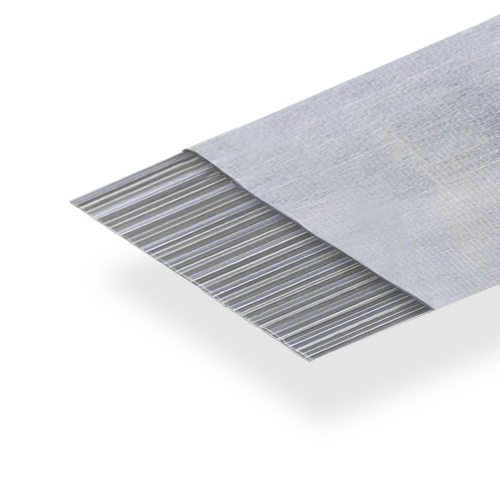

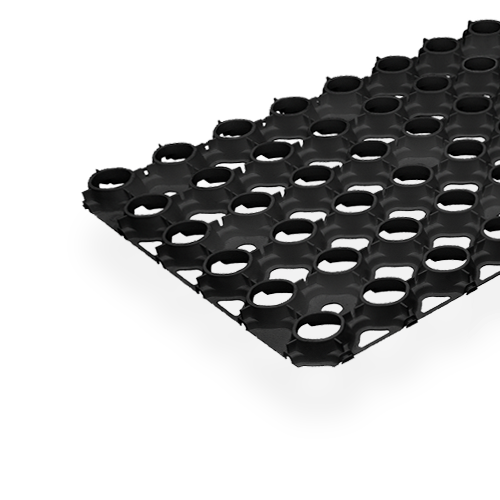

Traditionally any function of a geogrid that utilised the strength of the grid was referred to as reinforcement. While this is still correct, we also now use the word stabilisation to describe the function of a geogrid used in a pavement or foundation. This can be described as very low strain reinforcement where we look to the geosynthetic to provide aggregate confinement and interlock, thereby stiffening the basecourse material and producing a stiffened layer that is stronger than the sum of its parts.

A note on radial stiffness

Radial stiffness at 0.5% strain or 2% strain has become a common parameter quoted for geogrids used in foundations and pavements over the past 10 years. Its important to note that this is a modulus figure quoted at a certain strain and not a strength figure, therefore it results in much larger numbers than quoting the ultimate strength of the grid. For example, the ultimate strength of a grid may be 30 kN/m, and the strain at 2% may be 10.5 kN/m. This low strain stiffness figure would be quoted as 10.5 / 0.02 (strain as a decimal) giving a stiffness at 2% of 525 kN/m. It is also of note that radial stiffness, which is typically taken to mean the stiffness at the weakest point of the geogrids geometry, is not a design parameter and is not used as an input for pavement or foundation design.

Get expert advice

Geosynthetics is a well-established field of engineering which has proven its worth over many decades, however it is still not taught in many universities or technical institutes. In addition to this it is a rapidly advancing field and there are many new and exciting developments. For assistance with choosing the correct product for your project contact the team at Cirtex and let us work with you in making the smartest selection for your project requirements.