- Menu

- ProductsFeatured ProductsGeotextilesGeogridsReinforced Soil SystemsBlock Retaining SystemsGabionsTurf MattingGround CoversEarth AnchoringDewatering & DrainageDrainage CompositesImpermeable LinersPermeable PavingGeocellsRock Bags

- Contact Us

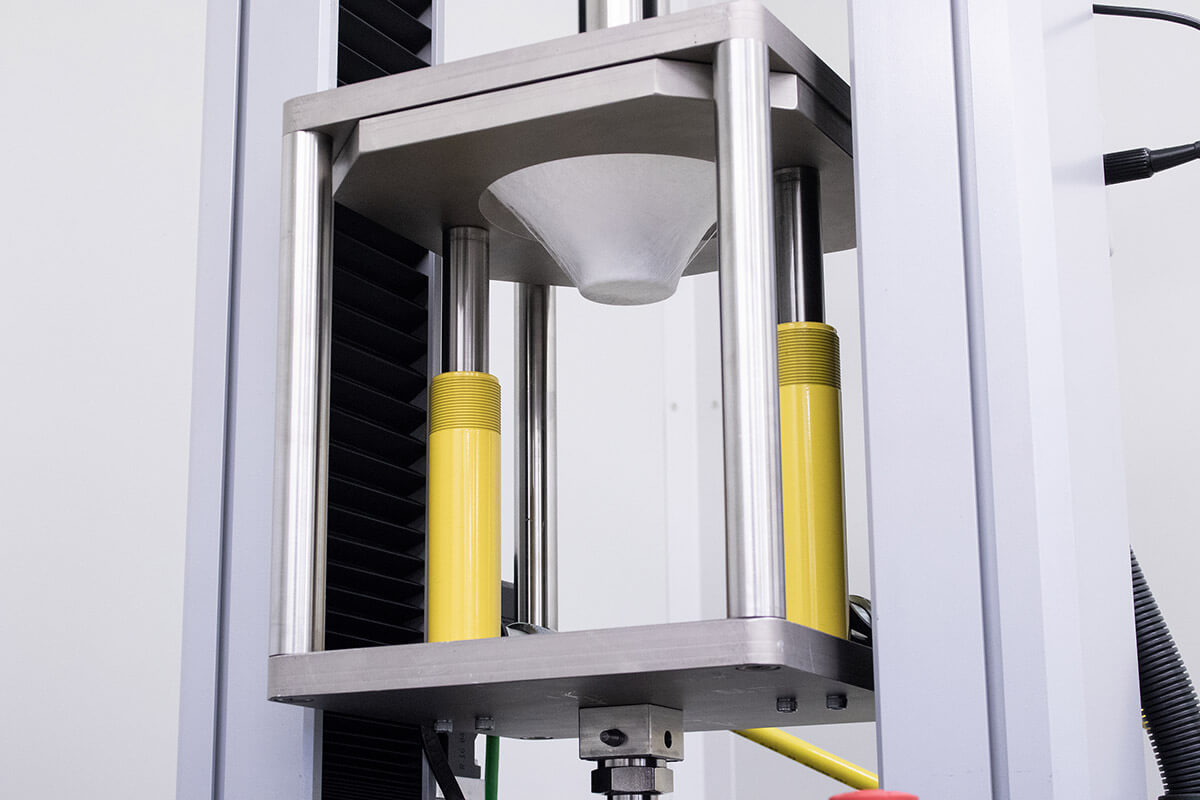

Introducing GeoCert Laboratory

Facebook

LinkedIn

Twitter

WhatsApp

A big step up for the industry

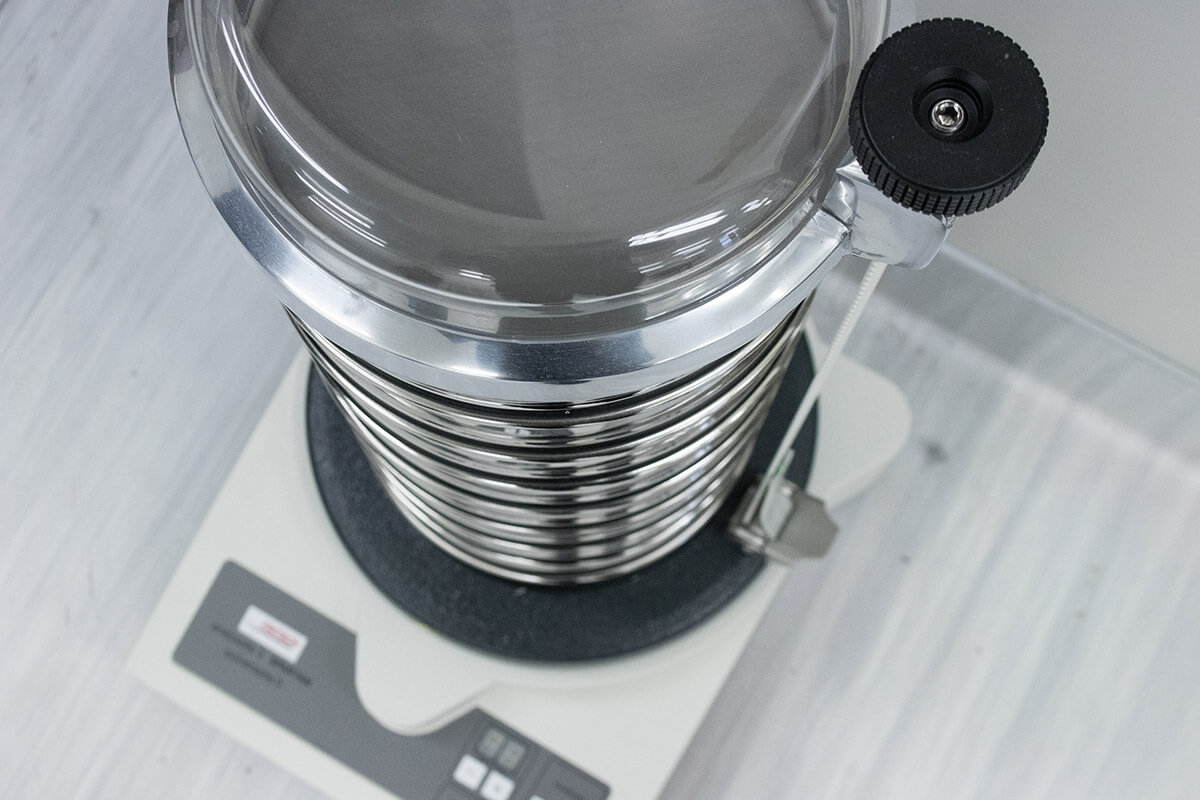

The introduction of an IANZ certified geotextile testing facility in New Zealand is a big step up for the industry. For many years the closest approved laboratories were in Australia requiring samples to be shipped internationally if any site samples required testing, or if a design engineer required a specific quality check or design assurance. Cirtex is pleased to announce the successful accreditation of the GeoCert laboratory in Thames specialising in materials testing for geosynthetic materials and covering a range of tests for geotextiles and Filter Sleeve™ to the appropriate AS and RMS standards.

The importance of independent certification

Independence and accuracy are core features of any testing laboratory. The results must be instantly trusted by all industry players, and in the event of any dispute, the systems and processes which ensure this independence and accuracy become even more important. The GeoCert laboratory operates under an ISO 9001 quality management system, however more importantly is accredited by IANZ for conformance to the much more rigorous and specific ISO 17025 standard. This certification means that the laboratories testing services, equipment and systems, along with the competencies of the operators are all audited to the strict requirements of this standard. In addition, the IANZ accreditation is internationally recognised and is part of ILAC-Mutual Recognition Agreement which includes major certification bodies like NATA and UKAS. Click here to learn more.

What do the tests mean and how are they used?

There are many tests that a civil or geotechnical designer may need for a geotextile to ensure it will perform correctly on site. Let’s drill down on a few of the most common ones to learn what they actually mean and how they are used.

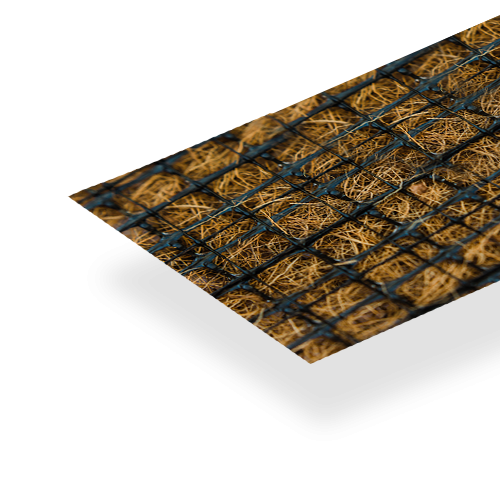

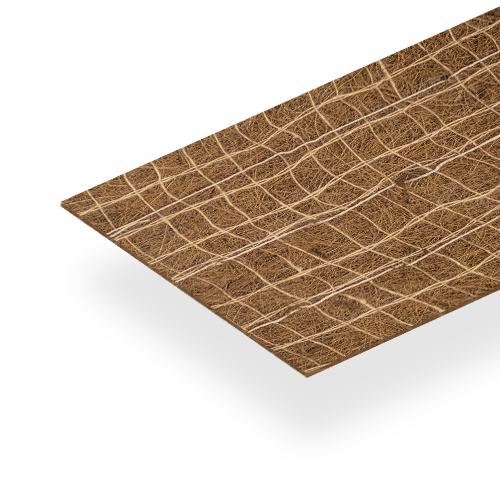

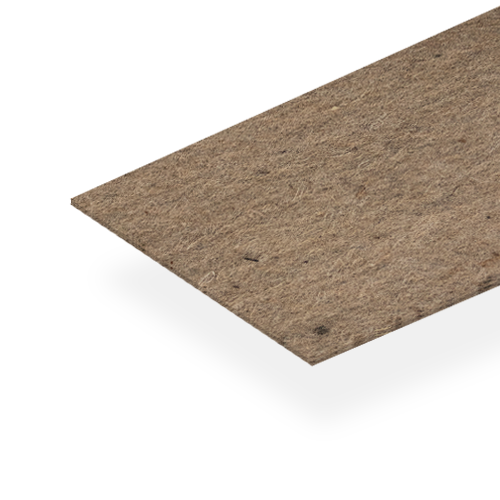

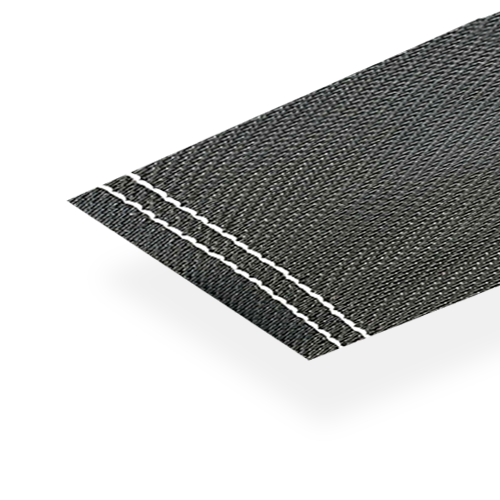

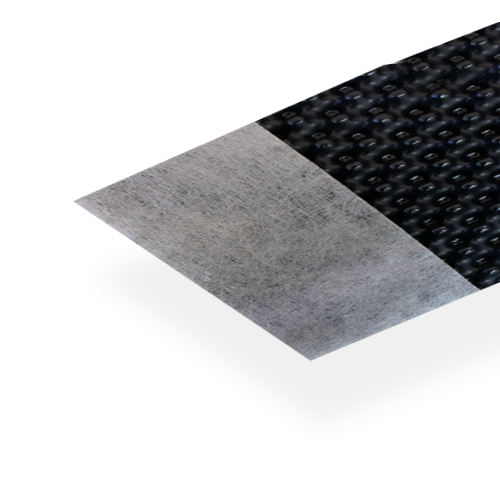

Common tests for non-woven needle punched geotextiles

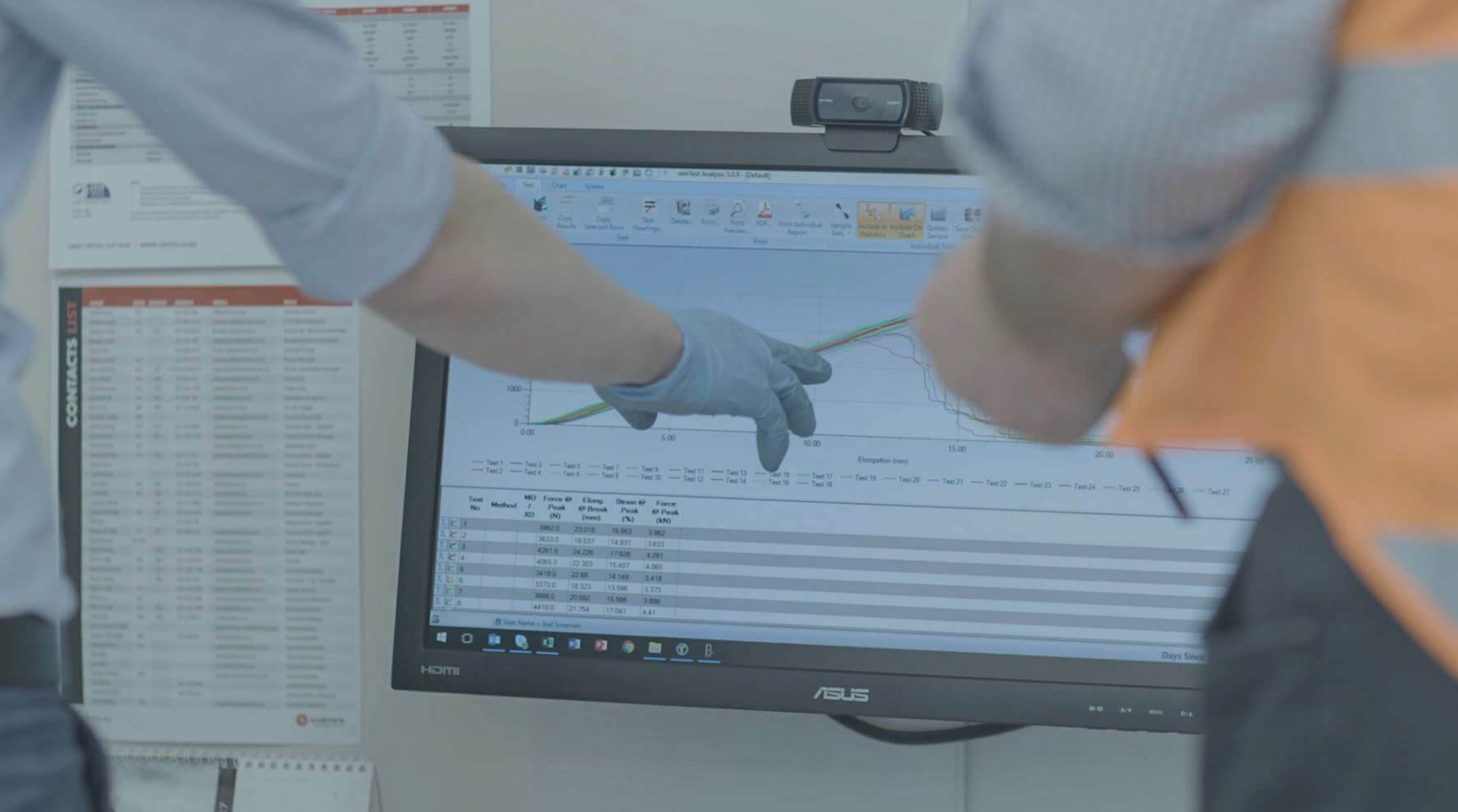

Mass and thickness. These are physical properties of the geotextile that are measured in the lab to a very fine level of accuracy. The mass is often used as an index property for quality control purposes and the thickness is relevant for the calculation of some hydraulic properties.

Grab strength measures the resistance of the textile to tearing in a 100mm strip of textile with a 25mm grip. This causes the fabric to neck up and stretch a lot. Grab testing is also an index test to get comparisons between different batches and products and is very different from a wide width test which uses a 200mm width for measuring resistance.

Trapezoidal tear testing measures the resistance of the individual fibres of a fabric to tearing by pulling a trapezoidal shaped sample. This is an important measure to gauge the resilience of the geotextile to damage on site

CBR puncture as the name suggests uses a 50mm plunger (similar to a soil CBR test) and forces the plunger into a sample of fabric held in a 150mm ring. The force generated to burst the fabric gives a good indication of strength and there are significant correlations between this test and a wide width tensile test.

Drop Cone testing is an impact test where a calibrated cone is dropped from a set height and the resulting hole is measured. It is especially relevant to gauge the resistance of a geotextile to puncture during installation

Pore Size testing is used to establish the effective opening size of the pores in the geotextile. This is an important parameter when designing for filtration.

Flow rate testing is used to measure the permittivity of the fabric (volume of water per unit of time) and the flow in litres per second normal to the plane.

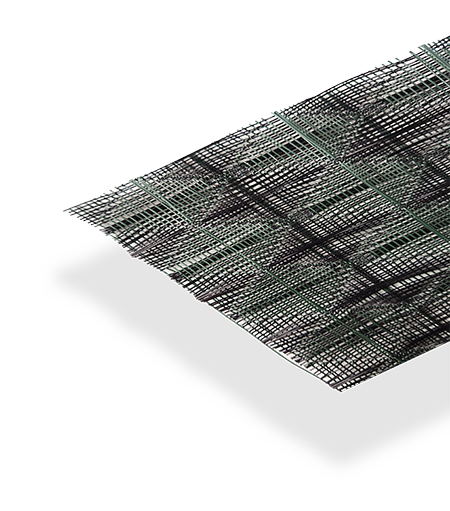

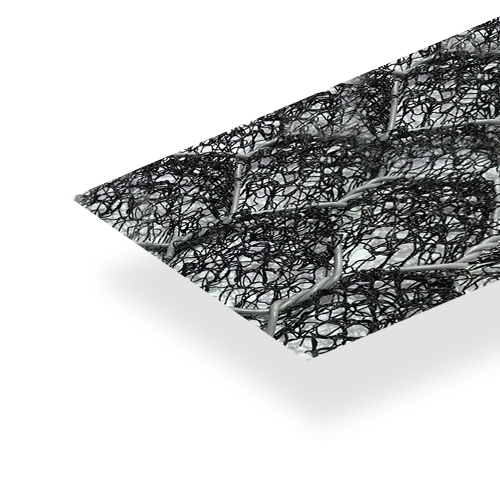

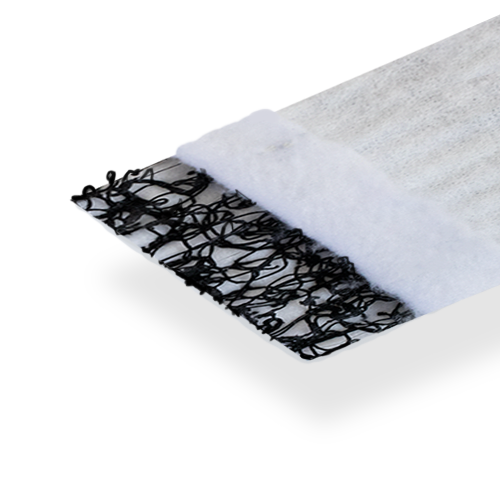

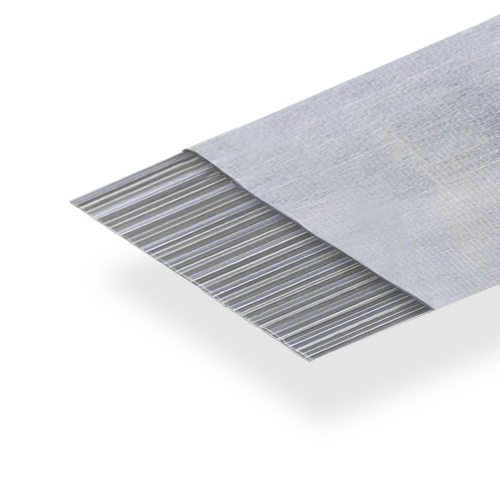

Tests for tubular knitted filter fabric (Filter Sleeve)

UV Degradation of the yarn for Filter Sleeve is not a concern for the installed life of the product as it is covered and protected from UV exposure; however, it can have a significant effect on the product during the distribution and installation phase. Therefore, the fabric is pre-treated in a specialist UV chamber before being tested to allow for this possible exposure.

Determination of Yield, Laddering & de-weaving, abrasion resistance and weave stability are physical tests to ensure the product is robust enough to survive the installation and perform satisfactorily once in place.

Opening Size on a Filter Sleeve is a very critical design parameter, as the product works to support a soil structure above the fabric, and the opening size combined with the weave structure needs to be within the correct tolerance to allow sand size particles to lodge above the fabric and form the soil filter.

Conclusion

The GeoCert laboratory is another big step for Cirtex and the industry in New Zealand as we demonstrate our commitment to being world class in everything we do. We are excited to be able to offer the services of the only certified geosynthetic materials testing laboratory in New Zealand to the market and look forward to demonstrating the benefits this facility can bring to civil and infrastructure projects throughout the country.