- Menu

- ProductsFeatured ProductsGeotextilesGeogridsReinforced Soil SystemsBlock Retaining SystemsGabionsTurf MattingGround CoversEarth AnchoringDewatering & DrainageDrainage CompositesImpermeable LinersPermeable PavingGeocellsRock Bags

- Contact Us

Types of retaining walls

Facebook

LinkedIn

Twitter

WhatsApp

What type of retaining wall is best for your application?

When we think of a retaining wall, we often default to the most common type we see around, or some favourite concept we have always had without researching the options available. Considering that retaining walls are one of the most expensive features of any earthwork’s development, commercial, industrial or residential its worth taking a moment to look at the benefits and costs of various types of walls. As well as the 5 points to consider we covered in our previous blog, the type of wall can have a huge impact on the success of your project.

The main purpose of a retaining wall is not to retain soil (although that of course is essential), the main purpose is to give you more usable land for your development, building or yard at the lowest practical cost with an acceptable service life and visual appeal.

While there are many descriptions of retaining wall types, the most common are embedded walls, gravity walls and MSE walls.

EMBEDDED WALLS:

Embedded walls use a structural element, usually timber or steel embedded into the ground with cross members such as timber planks or concrete sleepers to retain the soil above. The force of the earth pressure from the soil being retained is transferred to the ground in front of the wall by the posts. Therefore, the strength of the posts and the strength of the ground below the wall are critical. These types of walls are less economical when the ground is soft, as the posts need to be deeper, or closer together or both. Embedded walls are typically used for lower height retaining where they are most economical, or where space is severely constrained as they can be constructed very close to a property boundary or building.

GRAVITY WALLS:

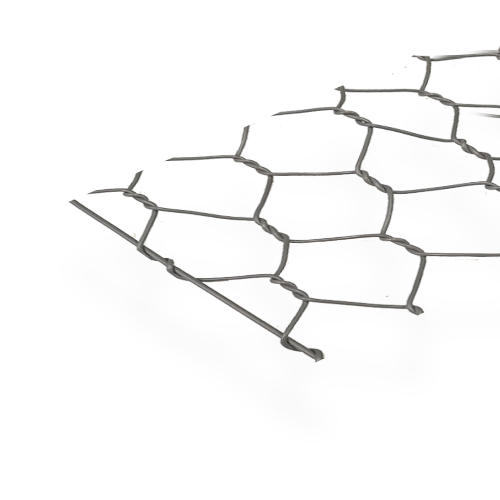

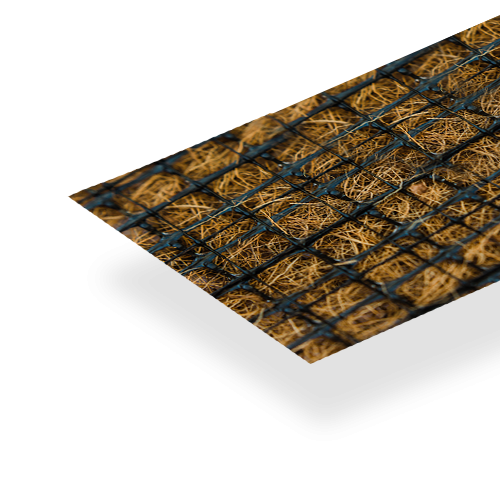

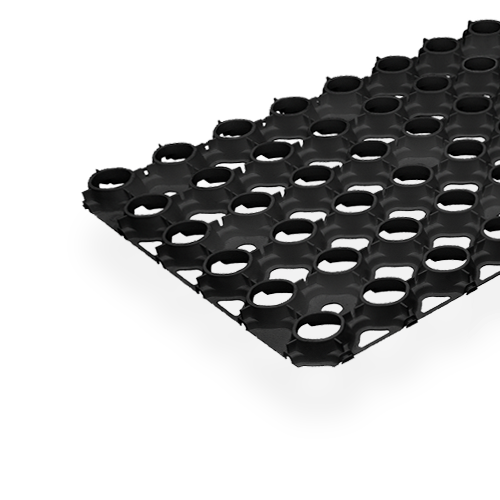

Gravity walls use the mass of the wall system to retain the soil. Common examples are gabions, concrete L section panels, Crib walls in timber or concrete, and concrete block systems. In most cases they have very little embedment, typically only 0.15 – 0.6m into the ground below and can be a good option for softer ground as they spread the load with a base area of around 40 – 50% of the wall height. The weight of the backfill soil above the wall can be used for added overturning and sliding resistance to increase wall stability.

MSE WALLS:

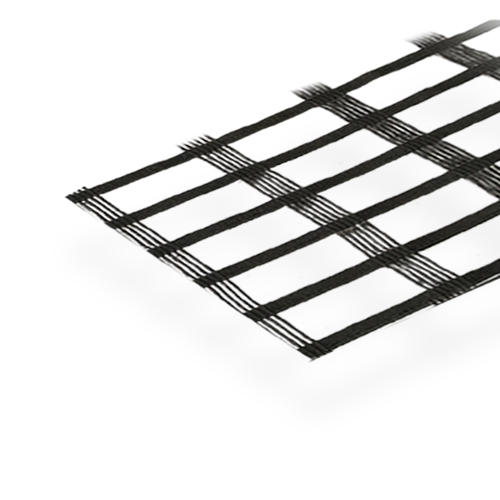

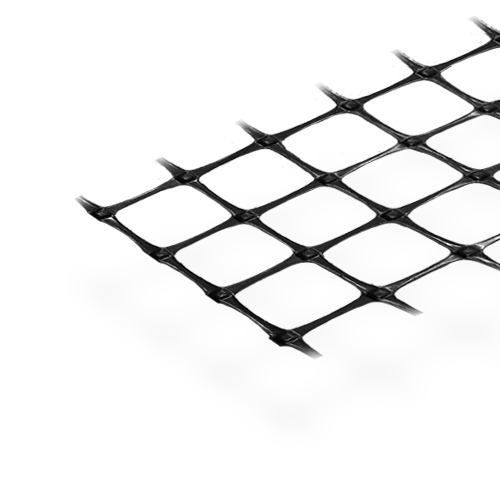

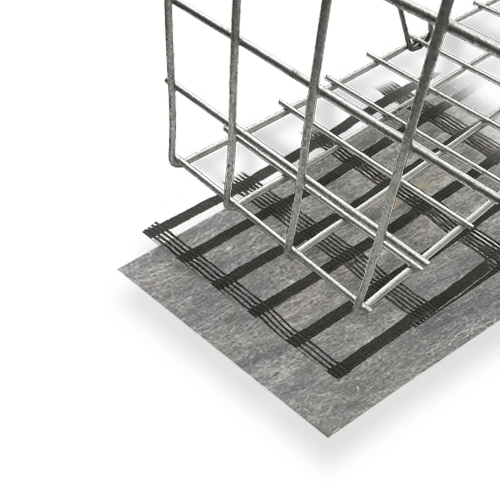

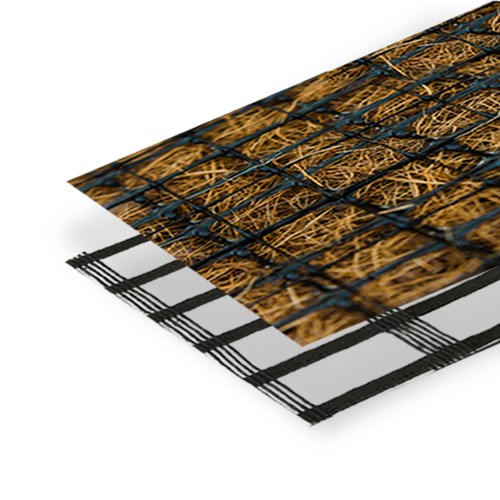

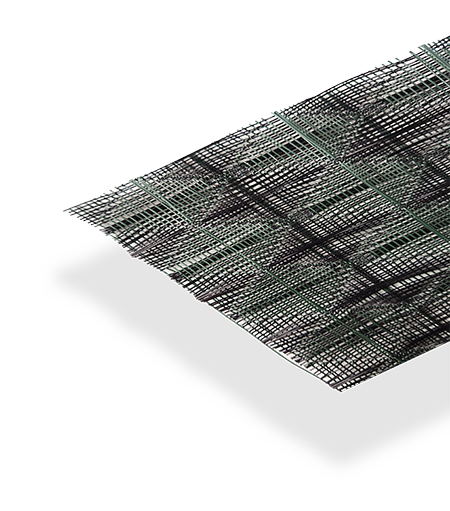

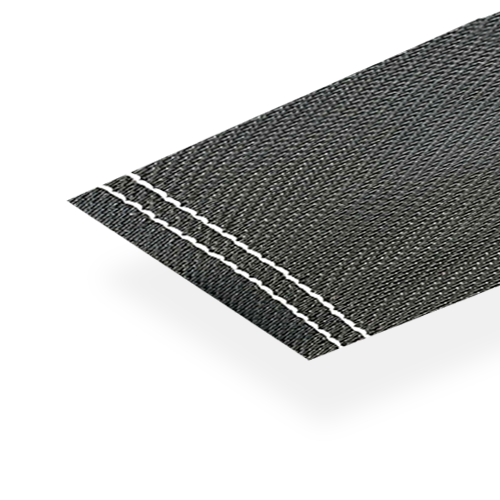

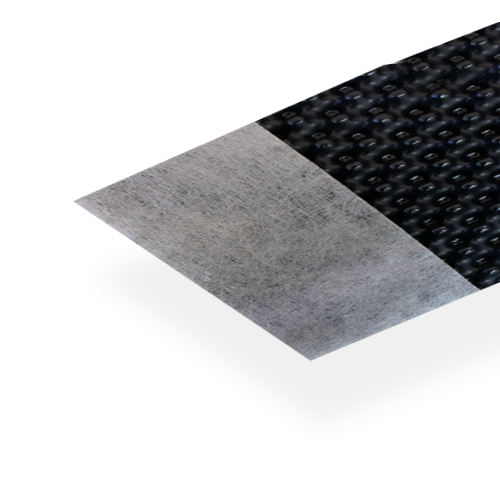

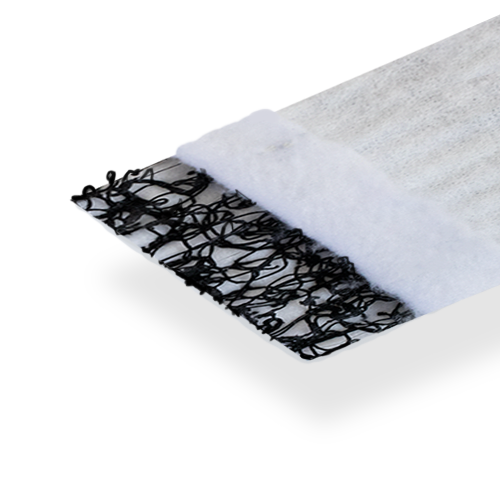

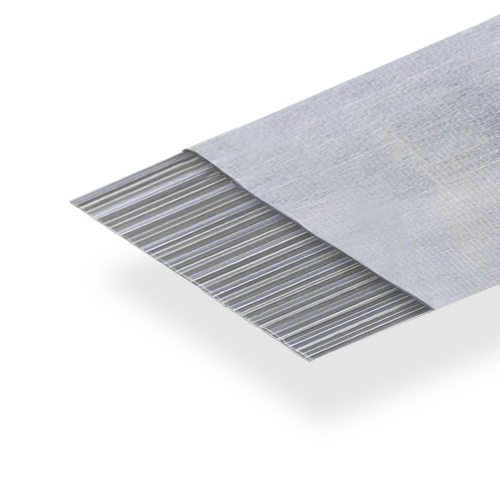

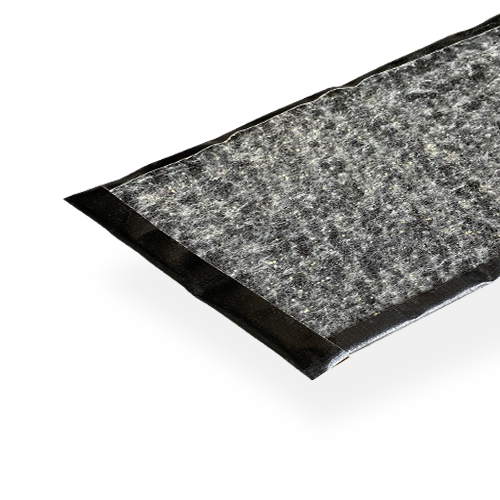

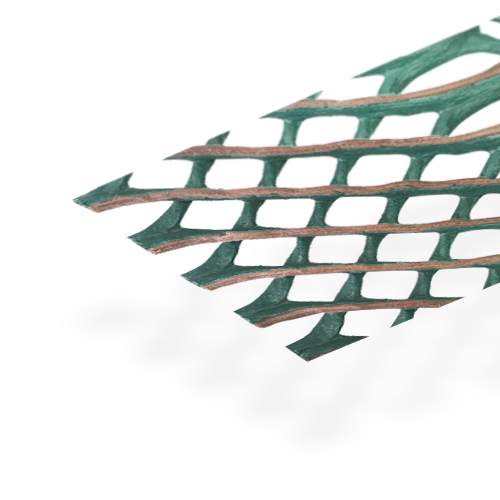

MSE walls, or Mechanically Stabilised Earth walls are a subset of gravity walls but quite distinct because the gravity mass is made up of soil, reinforced internally to make it stable. These types of walls can have many different facing options including concrete blocks or vegetated facing such as grass and creepers and are very economical especially for larger walls as they use readily available soils and aggregates for the main structure, combined with a small amount of geosynthetic reinforcement.

The MagnumStone system can be used to build either gravity walls or as a facing for MSE walls. For gravity walls MagnumStone uses the mass of the blocks, combined with extenders where required and the added weight of the gravel infill to form a stable mass with only the face of the block showing for a fast and effective retaining solution. For the MSE option MagnumStone blocks can be used as a facing element for the reinforced fill to provide long term performance and a visually appealing structure with over 100-year design life.

The best option for your site can be discussed with one of our specialist team but will depend on the distance behind the wall available for construction, the availability or otherwise of a good soil or aggregate to use for backfilling and the time constraints on the project among other things. Gravity walls with MagnumStone have a smaller footprint than the MSE option and can typically be constructed faster as there is very little earthwork involved compared to the MSE option, however the material supply cost can be more than an MSE wall, especially for walls above 2 – 3m high. MSE walls are an ideal solution for larger walls, with many case studies in Australia and New Zealand and around the world, with heights up to 15m and beyond possible.

Cirtex can assist your project team with recommendations on the best wall option, and in many cases can also provide preliminary projects concepts with material estimates and costings to assist with the scoping phase. Our team will also work closely with your nominated wall design professional to provide training on the use of the MagnumStone design software.